10 Essential Tips for Effective Oil Filtration: Improve Your Efficiency

Oil filtration is a critical process that significantly impacts the efficiency and longevity of machinery. In various industries, the cleanliness of lubricant oils directly correlates with the performance and reliability of equipment. To maintain optimal functioning and extend the lifespan of machinery, it's essential to implement effective oil filtration techniques. By removing contaminants, reducing wear, and minimizing the risk of catastrophic failures, proper filtration ensures that machinery operates smoothly under demanding conditions.

In this article, we will explore ten essential tips for effective oil filtration that can enhance your operational efficiency. These strategies will not only help you streamline your maintenance processes but also reduce costs associated with oil degradation and equipment downtime. By following these guidelines, you can ensure that your oil filtration systems are working at their best, leading to improved productivity and asset management. Join us as we delve into practical insights that can transform your oil filtration practices and support your overall machinery efficiency.

Understanding the Importance of Oil Filtration in Industry

Oil filtration is a critical process in various industrial applications, serving to enhance the longevity and reliability of machinery. In environments where machinery operates continuously, maintaining the cleanliness of the oil is essential. Contaminants such as dirt, debris, and metal particles can significantly reduce the lubricant's effectiveness, leading to premature wear and tear on equipment. Effective oil filtration ensures that these impurities are removed, thereby promoting optimal performance and reducing the likelihood of equipment failure.

Moreover, proper oil filtration plays a vital role in enhancing operational efficiency. Clean oil allows machinery to operate smoothly and at peak performance levels, which can lead to substantial cost savings in maintenance and repairs. By investing in an efficient oil filtration system, industries can also reduce their energy consumption, as clean oil reduces friction and resistance within machines. This not only extends the life of the equipment but also contributes to a more sustainable operation by lowering the overall waste produced from frequent oil changes and equipment replacements. Therefore, understanding and prioritizing oil filtration is essential for any industry reliant on machinery.

10 Essential Tips for Effective Oil Filtration: Improve Your Efficiency

| Tip Number | Tip Description | Impact on Efficiency | Common Challenges |

|---|---|---|---|

| 1 | Use the right filtration system for your application | Increases filtration efficiency, reduces contamination | Choosing inappropriate filter types can hinder performance |

| 2 | Regular maintenance of filtration equipment | Maintains optimal performance and minimizes downtime | Neglecting maintenance leads to increased operational costs |

| 3 | Monitor oil quality regularly | Ensures efficient filtration process and extends oil life | Inconsistent monitoring can lead to unnoticed degradation |

| 4 | Implement a filtration management system | Improves tracking and management of filtration processes | May require initial investment and training |

| 5 | Train staff on oil filtration practices | Enhances understanding of operations, reduces errors | Training can require time and resources |

| 6 | Select filters with appropriate micron ratings | Ensures effective removal of contaminants | Wrong ratings can lead to incomplete filtration |

| 7 | Set up a filtration schedule | Regular filtration reduces the risk of failure | Lack of adherence can result in over-filtering or under-filtering |

| 8 | Utilize online monitoring tools | Real-time data allows for proactive adjustments | Technology dependence can lead to vulnerabilities |

| 9 | Evaluate filter life and performance | Maximizes resource usage and minimizes waste | Failure to evaluate can lead to unexpected downtimes |

| 10 | Stay updated with industry standards | Ensures compliance and promotes safety | Changes in standards necessitate adjustments to processes |

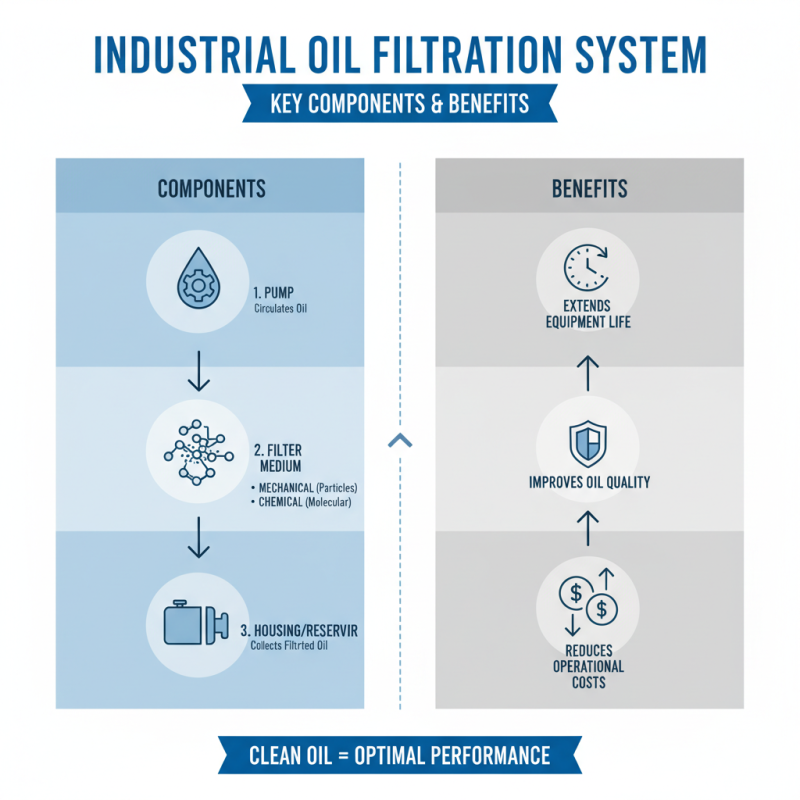

Key Components of an Effective Oil Filtration System

An effective oil filtration system is crucial for maintaining the quality and longevity of lubricants and oils in various industrial applications. Understanding the key components of such systems can significantly enhance operational efficiency. Central to any oil filtration setup is the filter medium, which can be either mechanical or chemical. Mechanical filters capture particulate matter, while chemical filters address contaminants at a molecular level. Selecting the right type depends on your specific requirements and the nature of the oil.

To optimize your oil filtration process, it’s essential to regularly monitor the filter's condition. A clogged filter can severely impact performance, causing inefficiencies and potential equipment damage. Implement a scheduled maintenance routine to inspect and replace filters as needed. Additionally, utilizing filtration systems with automatic sensors can help in real-time monitoring of oil quality, ensuring timely intervention when necessary.

Another crucial tip is to make use of filtration systems that incorporate multi-stage processes. A multi-stage filtration system effectively removes varying sizes of contaminants, providing a cleaner end product. This not only boosts the efficiency of machinery but also prolongs oil life. Investing in quality filtration systems and maintaining them properly is an integral part of ensuring smooth operations and reducing downtime in industrial environments.

Step-by-Step Guide to Choosing the Right Filtration Method

Choosing the right filtration method for oil is crucial to enhancing efficiency and maintaining quality in various applications. The first step is to assess the specific requirements of your operation. Consider factors like the type of oil being filtered, the presence of particulates or contaminants, and the desired viscosity post-filtration. Understanding these parameters will guide you in selecting the most appropriate filtration technology, whether it’s mechanical, chemical, or a combination of methods.

Next, evaluate the operational conditions. This includes the volume of oil being processed and the environmental factors that may affect filtration, such as temperature and pressure. For example, high-viscosity oils may require a different approach compared to low-viscosity ones. Additionally, look into the longevity and maintenance of the filtration system you’re considering. Regular maintenance not only extends the life of the equipment but also ensures consistent performance, thereby improving overall efficiency in your operations.

Common Mistakes to Avoid in Oil Filtration Practices

Effective oil filtration is crucial in various industries to ensure machinery longevity and operational efficiency. However, many practitioners overlook common mistakes that can jeopardize these goals. One significant error is neglecting routine maintenance and inspection of filtration systems. According to industry reports, 30% of machinery failures are attributed to inadequate oil filtration practices. Regular monitoring can significantly reduce this risk by allowing for timely replacements of filter elements and overall system assessments.

Another common pitfall is the improper selection of filtration media. Not all oils require the same filtration level; failing to match the filter type with the oil’s viscosity and contaminants can lead to suboptimal performance. A study highlighted that using the correct media can lead to up to a 40% increase in filtration efficiency. Understanding the specific requirements of your oil helps minimize the presence of sludge and particles that can cause wear and tear on equipment.

To enhance oil filtration efficiency, ensure you properly train your staff on filtration techniques. Many personnel may not fully understand the operational implications of poor filtration practices. Providing comprehensive training can contribute to reduced errors and improved maintenance protocols, directly impacting the bottom line. Additionally, routinely update your filtration system based on technological advancements in the field. Keeping abreast of new developments can optimize filtration performance and extend the life of both the oil and the machinery it lubricates.

Maintenance Tips to Enhance the Longevity of Filtration Equipment

Proper maintenance of filtration equipment is essential to ensure longevity and optimal performance. One of the most effective tips is to regularly check and replace filter cartridges according to the manufacturer’s guidelines. Neglecting this can lead to clogging, which not only hampers filtration efficiency but may also cause equipment damage over time. A proactive approach ensures that your system operates at its best, minimizing downtime and replacing parts when necessary.

Another critical maintenance tip is to keep the filtration area clean and free from debris. Regularly inspect the surroundings for any leaks or spills that could compromise the system's integrity. In addition, ensure that the equipment's housing and components remain dry and corrosion-free. Ensuring a clean operational environment extends the life of your filtration equipment and helps maintain efficiency.

Lastly, schedule routine inspections to identify potential issues before they escalate. Regularly monitoring various parameters such as pressure and flow rates can help pinpoint inefficiencies early on. By implementing a preventive maintenance program, you can enhance the reliability of your filtration systems while avoiding unexpected repairs and costly replacements.

Oil Filtration Efficiency Improvement

The chart above illustrates the efficiency scores for various essential oil filtration tips. Implementing these tips can greatly enhance the performance and longevity of your filtration equipment.

Related Posts

-

Unlocking Opportunities in Oil Filtration at China's 138th Canton Fair 2025: A Data-Driven Insight

-

2025 Top Oil Pumps: The Best Digital Solutions for Efficiency and Performance

-

Unlocking Clean Air: How Dry Air Filters Enhance Indoor Air Quality and Respiratory Health

-

2025 How to Choose the Right Air Tool Oil for Optimal Performance

-

How to Select the Right Fuel Oil for Your Industrial Needs

-

Unlocking Efficiency: The Best 2025 Oil Filter Tools for Every Mechanic's Needs